As the demand for clean, efficient, and compact energy solutions grows, two technologies stand out: Proton Exchange Membrane (PEM) Fuel Cells and Direct Methanol Fuel Cells (DMFCs). These advanced energy systems are transforming the way we power vehicles, devices, and backup systems with near-zero emissions.

In this post, we’ll explore the mechanisms, advantages, and real-world potential of both types.

Proton Exchange Membrane (PEM) Fuel Cells

PEM fuel cells are the most widely adopted type for automotive and portable applications, offering a strong combination of power density, clean operation, and fast responsiveness.

How They Work

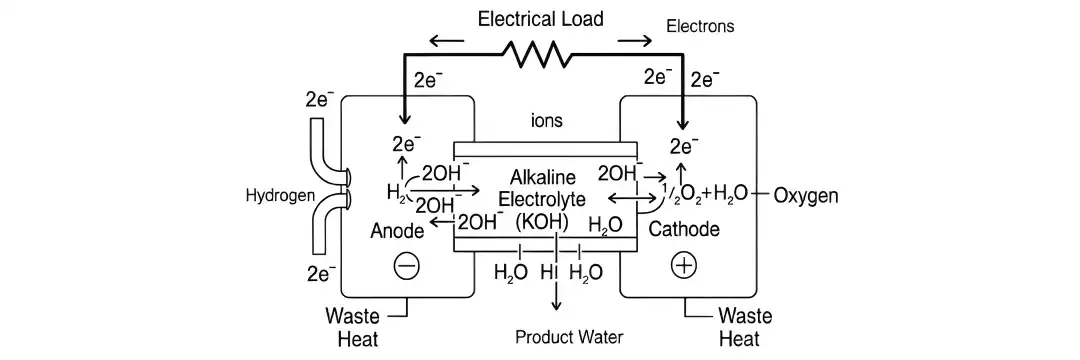

PEM fuel cells use hydrogen gas as fuel and oxygen from the air as the oxidant. Inside the fuel cell, a solid polymer membrane (often a form of acidified Teflon) acts as the electrolyte, allowing protons (H⁺) to pass through while forcing electrons (e⁻) to move through an external circuit—generating electricity.

Key Reactions:

Anode:H₂ → 2H⁺ + 2e⁻

Cathode:½O₂ + 2H⁺ + 2e⁻ → H₂O

Overall:H₂ + ½O₂ → H₂O + electricity + heat

Only by-product: water – safe, clean, and eco-friendly.

PEM Fuel Cell Benefits

- High power and energy density – more energy in less space

- Fast startup – ready to go in seconds

- Low operating temperature – safer and easier to manage

- Solid-state electrolyte – no liquid to leak or corrode

- Uses ambient air – tolerant to CO₂

- Compact and rugged – ideal for vehicles and portable use

- Safe operation – low pressure systems reduce risk

PEM Fuel Cell Challenges

- Sensitive to carbon monoxide and sulfur – even small amounts can reduce efficiency

- Humidification required – needs water management systems

- Expensive materials – platinum catalyst and specialty membranes

- Limited operating temperature – restricts combined heat-power uses

Direct Methanol Fuel Cells (DMFCs)

A variant of PEM technology, DMFCs run on liquid methanol—offering a simpler fuel storage solution without the need for compressed hydrogen.

How DMFCs Work

At the anode, methanol reacts with water:CH₃OH + H₂O → 6H⁺ + CO₂ + 6e⁻

At the cathode:3/2 O₂ + 6H⁺ + 6e⁻ → 3H₂O

Overall Reaction:CH₃OH + 3/2 O₂ → CO₂ + 2H₂O + electricity

DMFCs produce carbon dioxide and water, but don’t require external hydrogen storage.

DMFC Advantages

- Liquid fuel – easier to store and transport

- No external reformer needed

- Compact design – suitable for portable devices

- Continuous operation – fuel can be refilled while running

DMFC Disadvantages

- Lower energy efficiency compared to hydrogen-fed PEMs

- CO₂ emissions – not entirely emission-free

- Technology still maturing – limited large-scale adoption

- Less powerful – lower output limits its industrial use

PEM vs. DMFC: Quick Comparison

| Feature | PEM Fuel Cell | Direct Methanol Fuel Cell |

| Fuel | Hydrogen gas | Liquid methanol |

| Output | Water | Water + CO₂ |

| Efficiency | High | Moderate |

| Startup | Fast | Fast |

| Use Case | Vehicles, large systems | Portable, low-power |

| Infrastructure | Requires hydrogen supply | Easier fuel logistics |

| Current Status | Commercially viable | In development |